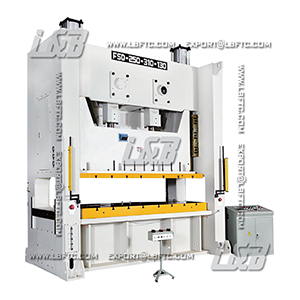

Application:

Suitable and specially designed for the aluminum alloy, copper, stainless steel, carbon steel and thin iron products industries. It is particularly suitable for deep drawing and forming of stainless steel thin plates. Major products include punching, flanging, and deep drawing of aluminum alloy and composite materials for kitchenware, household appliances, and metall containers, as well as the production of automotive shock absorber trays, engine oil pans,and metal housings.

◆ The equipment can be equipped with forming tonnage and stroke of the sliding plate arbitrarily according to the forming needs of actual parts;

◆ The main hydraulic cylinder adopts the structure of piston-type, with the embedded quick rod controlling the machine to rapidly descend;

◆ The equipment excels in the application of reverse drawing, which is more suitable for deep drawing of ultra-thin plate, effectively reducing the mold cost and simplifying the mold structure;

◆ The clamping cylinder can be equipped with a servo control system, which can realize the real-time adjustable clamping force according to the dynamic change requirements;

◆ The closed-loop control is adopted, and the clamping force is more uniform, ensuring the precision and consistency of product quality;

◆ The applicable materials include stainless steel, carbon steel, copper, aluminum plate, and composite materials, with the minimum wall thickness of s0.2mm and the maximum wall thickness of 5mm. The drawing product diameter can reach up to 2000mm;

◆ The column guide sleeve is designed and manufactured using the patent, which has good wear resistance and guidance, and is easy to maintain.

Want to understand more information of this product, please contact us, we will reply more for you. Thanks!